TAKING A STAND: UNVEILING THE REALITY OF “1-DAY” CONCRETE COATINGS

In a piece published in August 2020 by GarageFloorCoating.com (“Polyurea-Polyaspartic One-Day Systems: Do They Work“), the potential risks connected to “1-day” coating systems are discussed. These garage floor coatings have grown considerably popular due to their ease of application and product/labor-saving benefits for contractors. Likewise, clients appreciate them because they can be installed within a single day. However, don’t overlook the classic principle of caveat emptor (“Buyer beware”). Ponder this. Does speed ever equate to quality in the realm of contractors?

What’s a Polyurea and Polyaspartic?

Favored for its quick-curing properties among concrete industry professionals, polyurea and polyaspartic coatings serve as excellent protective coatings against UV radiation, chemical degradation and physical impacts. (It’s important to note that the terms “polyurea” and “polyaspartic” are often used interchangeably, given that a polyaspartic is in fact an “aliphatic polyurea”). Polyaspartics (aliphatic polyureas) are excellent for use as robust clear topcoats and (quality ones) even prevent hot-tire transfer. However, polyurea-polyaspartics have one major Achilles heel – they’re simply not spec’d for use as “direct-to-concrete” primer coats, especially where high moisture conditions exist.

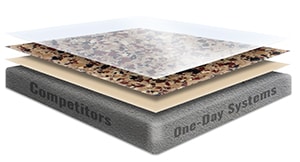

Conscientious contractors get around this problem by using a moisture-mitigating epoxy as the primer coat and using the clear polyurea-polyaspartic as topcoats only. But since epoxies take more time to dry (“cure”) – coating system installations typically take two days instead of one! “1-day” providers may attempt to devalue epoxies (because the 1-day guys ONLY use polyurea-polyaspartics, nothing else), but fail to convey to their customers the unique strengths and weaknesses of the various coating types. For instance, while epoxies make great primers, they tend to fade under UV light exposure – so they make for poor topcoats. Conversely, polyurea-polyaspartics excel as topcoats, but fail as adequate primers because they don’t do well if exposed to high hydrostatic pressures – they tend to delaminate.

Those who promote “1-day polyurea” coatings know this dichotomy and so adjust their customer contracts accordingly. They include small print which conveniently excludes warranty claims for “moisture-related problems” (including high hydrostatic pressures), and in doing so, safeguard themselves when the coatings peel up. Understanding the important properties, pros and cons, of the different types of concrete coatings – epoxies, polyurethanes, and polyurea-polyaspartics – and using them accordingly, is the way in which reputable professionals produce the best, industrial-grade concrete coatings.

Why Are Moisture-Related Issues Not Covered In “1-Day” Systems?

Applying a thin layer of polyurea-polyaspartic direct-to-concrete in “1-day” applications is ill-advised, as this can lead to delamination under medium to high moisture conditions. This method of application, however, appeals to contractors, because it requires a lesser amount of liquid coatings and labor (thus increasing their profit). As cover, the warranties of “1-day” installers typically exclude moisture-related issues…and in some cases, staining caused by plasticizer migration (“hot-tire” transfer). With these shortcomings, why would anyone invest in a “1-day” polyurea coating system?

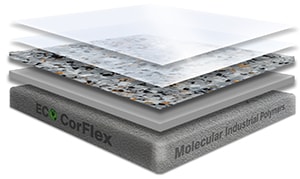

Us Versus Them

Our company guarantees that our thick, garage floor coverings are resistant to tire marks, most automotive fluids, and moisture-related damage. We take pride in consistently using an epoxy primer, topped with industrial-grade 100%-solids polyurea-polyaspartic coatings, applying two clear top coats (not 1) for maximum protection in our full-flake coating systems. We’re a 2-day installation company and we strictly avoid the use of a direct-to-concrete polyurea-polyaspartic primer. This ensures longevity of our coatings.

We also differentiate ourselves from competitors through our use of exclusive, mica stone blends within several of our full-chip series of concrete coatings – this flooring goes above and beyond standard thermoplastic flakes. Our floors offer greater thickness (over 35 mils), strength and visual appeal.

For exceptional, long-lasting, commercial-grade garage floor coatings, contact us at your earliest convenience by clicking here to request your free estimate.